Manufacturing Services

rms delivers superior product solutions through our talented employees utilizing the latest in machining and manufacturing technologies.

rms delivers superior product solutions through our talented employees utilizing the latest in machining and manufacturing technologies.

By making significant annual investments in the latest machine tool technologies, rms maintains a significant advantage in both capability and capacity. This translates into more than 600 State-of-the-art machine tools in a range of platforms, selected for their ability to provide the best tolerance control, spindle speeds and surface quality in the industry. It also assures that rms is constantly evaluating and updating to the best technologies available so that we remain at the forefront of machining capability. For our customers this means the best quality and lowest delivered cost.

The following represent the typical tolerance guidelines but as we continue to push the boundaries through new technologies these do not necessarily represent the final limits of capability.

| Machine Type | Material Stock |

|---|---|

| High-speed 5-axis mills | 0.010" (0.25 mm) to 18.0" (460 mm), cylinder or square |

| 13-axis Swiss | 0.060” (1.52 mm) to 1.5” (38 mm), cylinder or square |

| Lathe turning | 0.05” (1.27 mm) to 4.0” (100 mm) |

| 5-axis Wire EDM | 0.025" (.635 mm) to 14.0" x 8.0" x 9.0" (355.0 X 203.2 X 228.6 mm) |

| 4-axis RAM EDM | |

| Femto second laser | |

| *Fine cut Nd:YAG Laser | |

| Laser welders | titanium, platinum, stainless steel |

| Machine Type | Material Stock |

|---|---|

| High-speed 5-axis mills | 0.010" (0.25 mm) to 18.0" (460 mm), cylinder or square |

| 13-axis Swiss | 0.060” (1.52 mm) to 1.5” (38 mm), cylinder or square |

| Lathe turning | 0.05” (1.27 mm) to 4.0” (100 mm) |

| 5-axis Wire EDM | 0.025" (.635 mm) to 14.0" x 8.0" x 9.0" (355.0 X 203.2 X 228.6 mm) |

| 4-axis RAM EDM | |

| Femto second laser | |

| *Fine cut Nd:YAG Laser | |

| Laser welders | titanium, platinum, stainless steel |

| Features | Typical Limits | Extreme Limits |

|---|---|---|

| Diameter | +/- 0.0005" | +/- 0.0001" |

| Length | +/- 0.001" | +/- 0.0005" |

| Profile | 0.002" | 0.001" |

| Position | 0.002" | 0.001" |

| Surface finish | 16 Ra | 4 Ra |

| Sharp corners | 0.003" | 0.001" |

| Wall thickness | 0.005" | 0.002" |

| Pocket milling depth | 3x to 6x diameter | 7x to 10x diameter |

| Inside fillets | 0.005" | 0.002" |

close {x}

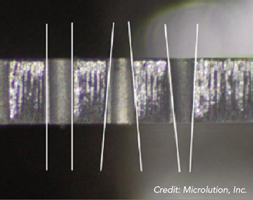

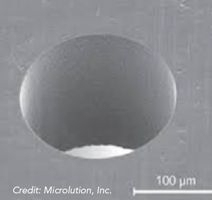

In response to the needs of the medical device industry, rms has invested in a new femtosecond laser machining platform to support its advanced machining operations. This precision laser technology excels at small features and can drill holes as small as one thousandth of an inch in diameter which is well beyond the capability of conventional drilling technology. Further, the holes can be cylindrical, positive or negative taper, or elliptical. In addition, this laser utilizes an ultrafast pulse, essentially creating an athermal process. This in turn eliminates the normal heat affected zone that can degrade the properties of the material and require additional secondary processing.

Taper Capabilities

Micro gear with 0.2598_diameter

Sample hole

close {x}

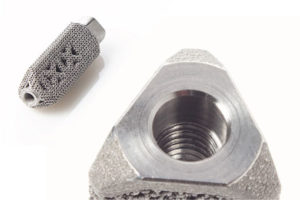

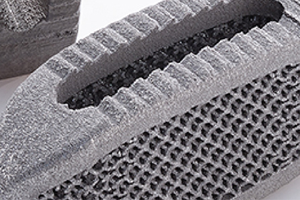

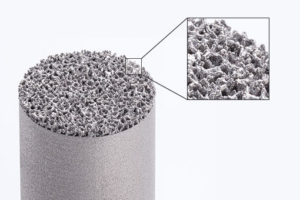

To support the manufacture of Orthopaedic implants rms has invested in Direct Metal Printing (DMP) as a strategic technology for product development and manufacturing. Also known as Additive Manufacturing, this proven technology is gaining acceptance in the manufacture of implantable medical devices by offering a number of benefits that cannot be replicated through machining alone.

Foremost among its benefits, Additive Manufacturing provides a method to manufacture highly complex parts that simply cannot be produced with conventional machine tools and processes. These designs promote better in-growth of bone using printed trabecular surfaces and internal matrix structures that were not possible until now. In combination with our machining capabilities, we have the ability to add secondary features to the devices created by Direct Metal Printing, delivering a finished product solution from a single source.

Secondary machining of printed implants

Spinal Implants

Printed porous structure

close {x}

rms Company has assembled a complete array of secondary operation capabilities to assure that your finished components meet the most exacting standards.

close {x}

Taking the process a step further, rms has the resources to convert components we machine into sub-assemblies and assemblies to further reduce your inventory requirements and assembly time.

close {x}

To provide the widest range of available finishing options, rms has also developed a network of approved and qualified outsource partners.

close {x}

We are a part of the Cretex family of medical companies, a privately owned enterprise with a proud 100-year history. We offer a complete range of medical device manufacturing expertise and bring you the convenience of billing simplicity, no markups and faster decision-making. We also have the financial strength and resources you may need to match your latest manufacturing technology needs.

By bringing the best together through technology and talent, Cretex Medical can offer a broad range of solutions with capabilities that include:

![]()

![]()

![]()

![]()

![]()

close {x}