rms Company News

Tag: Medical Device

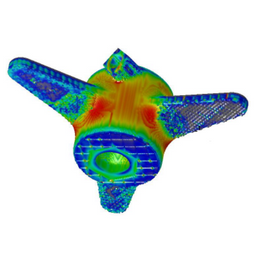

Additive Manufacturing from Powder to Final Product

rms Company is one of the largest contract manufacturers of high-quality, tight-tolerance medical devices in the world and operates one of the leading additive manufacturing cells in the U.S. Learn about rms Company’s additive operation from titanium powder to cleaned, finished part in this additive manufacturing video series.

Heat Treating Your AM Products: Why it’s Necessary and How to Choose the Best Process

New users of metal additive manufacturing (AM) may not realize nearly everything made via metal AM needs to undergo some degree of heat treatment following the AM process. There are exceptions, but it is usually a good idea to heat treat your products – especially if they are for a demanding application like the medical implants produced at rms Company.

Cleaning Coupon Increases Efficiency and Ensures Quality for AM Processes at rms Company

One of the most well-known benefits of additive manufacturing (AM) is the ability to integrate elaborate surface technologies. These technologies, such as lattices and gyroids, allow for improved bone adherence to the textured surfaces. However, these surfaces also pose new cleaning challenges.